Apex Summerhouse

Apex Summerhouse

From- 10-year guarantee

- Special formula enhanced preserver

- High grade Scandinavian tongue and groove timber

- Heavy duty framing at 44x28mm

- Pre-fitted toughened glazing

Configure & Buy

Size

Choose delivery within 3-5 working days

From

Experience the full power of outdoor living.

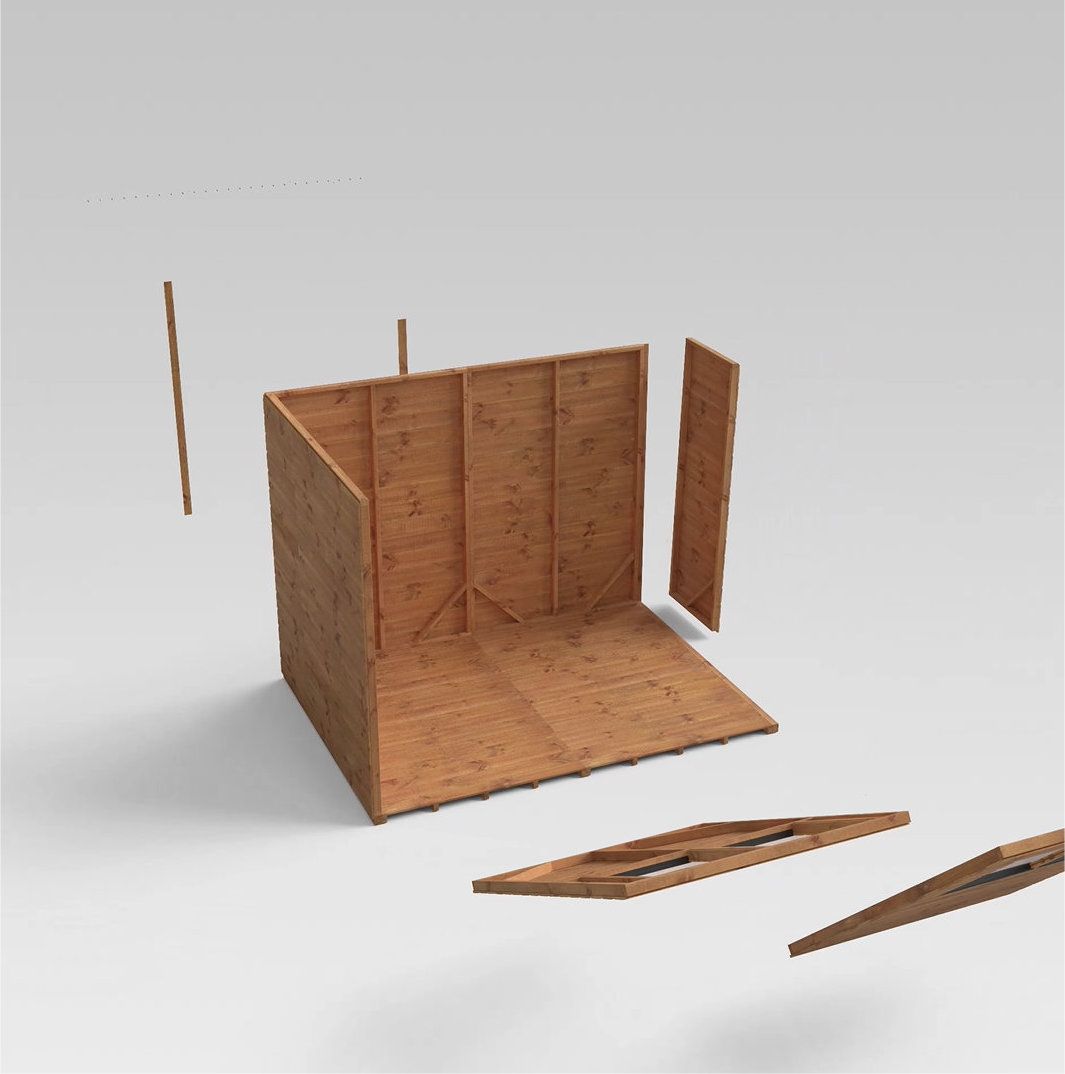

Simple to put up. Tough to knock down.

Quality guaranteed.

Every summerhouse is guaranteed for 10 years against timber rot, decay or insect infestation. But expect it to last 25.

Adaptable to your needs.

Setup a garden office, a workshop, or create a relaxing retreat. Our summerhouses can be assembled with windows and doors in any configuration you like, to fit your space just the way you like it.

DIY or don’t.

We make assembling your Powershed powerfully simple, with tried and tested instructions and videos.

But if DIY isn’t your thing, we can point you in the direction of an expert fitter.

A solid base for a powerful summerhouse.

All summerhouses must be assembled on a firm and level base to give the summerhouse a solid foundation and maximise the longevity of the building. Remember, all our summerhouses come with flooring, unlike some of our competitors.

For information on bases, please visit our build a base guide

Or make things easier with a Powersheds Base Kit

Want someone to do it for you? See our base directory