Shed Felt Buyers Guide

Types of Roofing Felt for Sheds

There are many types of shed felt which differ in price and quality, but what’s the best roofing felt for sheds? We've compiled a list of the most common types and explained the differences:

Sand backed shed felt:

Sand backed shed felt is non-breathable roofing felt base sheet suitable for roof waterproofing, operating as a base sheet in a 2-layer system. Some companies offer this for a shed roof which, but without another felt on top, we wouldn't recommend.

Ragged / Paper backed shed felt:

Ragged back felt or paper-backed shed felt is a felt where the backing is made from rags or paper. A green mineral is then put on top and then heated and cooled so that the green mineral sticks. Although suitable for a shed, it can tear quite easily, so it doesn’t last as long as polyester felt.

Polyester backed shed felt:

Shed felt which comes with ‘polyester’ backing lasts longer and doesn’t ripple or tear easily. The felt is saturated with bitumen (asphalt), which repels water but still allows the product to breathe. The material is strong and resilient, allowing it to last longer, helping keep your shed waterproof while permitting air/moisture from inside your shed to escape. This is also the felt material we use on all our sheds at Power.

The following video explains our polyester backed felt in greater detail:

Do Shed Roofs Come Pre-Felted?

It’s not often that sheds come pre-felted. Some manufacturers pre-felt pent roofs before delivering if they are also assembling (to reduce assembly time). However, it is rare to pre-felt a shed roof prior to delivery if the customer has to install the roof. It is difficult to pre-felt an apex roof as the roof has multiple panels.

Do You Need Adhesive for Shed Felt?

This is not necessary for a shed – the clout nails will be secure enough to hold the felt down in position.

How to Install Roofing Felt on a Garden Shed

Apex roof:

To felt an apex shed roof, you have to roll out the polyester-backed felt along the lower part of one side of the roof, allowing for sufficient overhang to fold down onto the roof framing (but not the underside of the roof).

Use clout nails to tack along the top edge of the felt and into the roof boards. Repeat this process on the other side of the roof. Once done, fold the overhanging felt at the gable ends under the roof boards and tack it into place.

Pent roof:

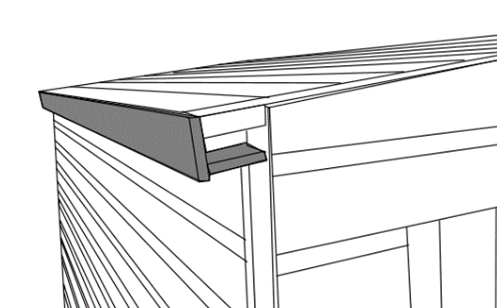

Before laying the felt on a pent shed , you will need to attach the back bargeboards with the 40mm galvanised nails. There are two for the back – one at the edge of the roof and one on the underside. These soffits may come in more than one section and may need cutting down to size with a saw depending on which size shed you’ve chosen. Be sure not to mix these up with the corner strips and cover lats which are to go vertically around the shed in corners and covering joins.

Roll out the mineral roofing felt along the lower part of one side of the roof, allowing for sufficient overhang to fold down onto the roof bargeboard (but not the underside roof bargeboard). Use clout nails to tack along the top edge of the felt into the roof board and the bottom edge of the felt into the back bargeboard. Repeat this process along the higher part of the roof. Fold down the overhanging felt on the gable ends and tack this into place. Front and side bargeboards will cover any untidy edges.

Important: Use Step Ladders to put on the roof felt but do not climb on top of the roof. Ensure there is a second person to support you when using a ladder.

How Long Does Shed Roof Felt Last?

Shed felt will typically last around 5 years. However, if you go for a shed with a polyester backed shed felt, this can last up to 15 years. Although polyester backed felt is the same thickness as standard, it is much stronger and more difficult to tear, so it lasts longer.

A good way to increase the longevity of felt is to add an underlay felt which will add a layer of protection and is commonly used for roofs with a shallow pitch (to avoid water capillary action).

How to Dispose of Roofing Felt?

You can simply take the old felt to your local household waste depot/council tip. You may wish to remove any nails from the felt prior to discarding it.

How Much Shed Felt Do I Need?

This will depend on the size shed you have. Please check with the shed supplier on how much you should have if you feel you do not have enough. Felt tends to come in various lengths but are generally 1 meter wide. You would need to overlap the felt by around 4 inches to avoid water running back up the felt (capillary action) which can cause the roof to leak.

Won't the Nails Cause Holes in the Shed Felt and Cause it to Leak?

If you are to install shed felt then you would need to ensure you use clout nails. Clout nails are self-sealing so when you hit the nail down it creates its own seal in the felt. They also come with a large head to minimise the chance of water leaking through. Installing the felt onto your shed is actually an important part of waterproofing your shed.

What Colour is Shed Felt?

Shed felt is mostly green due to the minerals that are set onto the backing. However, you can also get red and black shed felt.

Alternatives to Felt for a Shed Roof?

EPDM:

A synthetic, man-made rubber membrane created by mixing a range of raw materials together which are pressed and rolled into strips through extrusion. EPDM has a host of pros most noticeably its life expectancy which is 50 years. However, the downside is it's much more expensive than felt, almost double in some instances.

Shingles:

Shingles can be made from a variety of materials such as wood, slate or plastic and can offer a more attractive finish to your garden building. Shingles themselves are individual overlapping elements, typically flat rectangular shapes laid from the bottom of the roof up.